Applied area: remote sensing satellites, unmanned aerial vehicles, and large machinery fault diagnosis.

Introduction:

The magnetic fluid angular velocity sensor is used to measure broadband micro-angular motion, which adopts fluid kinematics to sense and measure the spectrum response of micro-angular motion.

It has features of integrated lightweight, wide frequency, high precision, low power consumption, which can meet the application requirements of accurate measurement of high-frequency micro-angular vibration sources and high-frequency angular vibration features.

By obtaining micro-angular motion information, the ability of application systems such as optical remote sensing image quality compensation, line of sight stabilization in optical communications, directed energy systems (including laser, particle beam, and radio frequency), large mechanical platform fault prediction, ultra-quiet platforms, collision impact test can be improved.

This product has broad market prospects which is suitable for commercial remote sensing satellite laser communications, ground astronomical observations, drones, ultra-precision machining and etc.

Features:

It has features of integrated lightweight, wide frequency, high precision, low power consumption, which can meet the application requirements of accurate measurement of high-frequency micro-angular vibration sources and high-frequency angular vibration features.

By obtaining micro-angular motion information, the ability of application systems such as optical remote sensing image quality compensation, line of sight stabilization in optical communications, directed energy systems (including laser, particle beam, and radio frequency), large mechanical platform fault prediction, ultra-quiet platforms, collision impact test can be improved.

This product has broad market prospects which is suitable for commercial remote sensing satellite laser communications, ground astronomical observations, drones, ultra-precision machining and etc.

Features:

It can obtain both angular displacement information and angular velocity information;

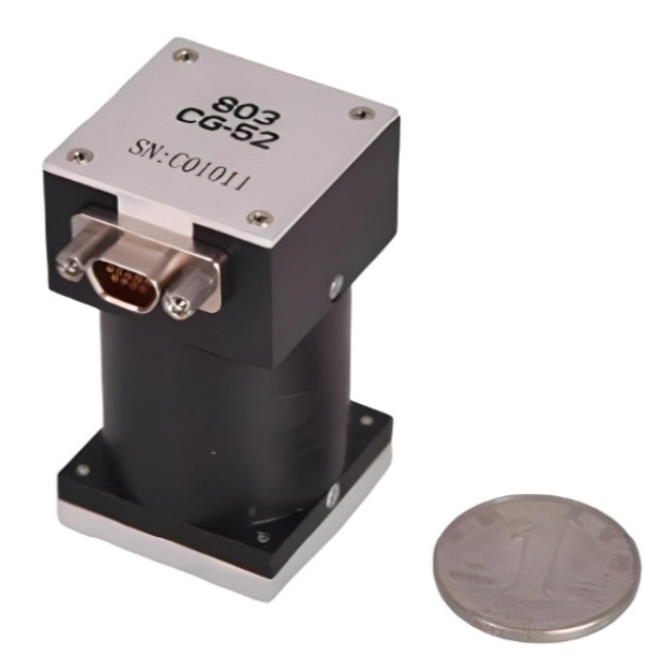

Small size, light weight, low power consumption;

Insensitive cross-axis and linear acceleration;

High reliability, free from moving parts;

Strong environmental adaptability;

Impact resistant, no mechanical saturation;

Support customized production on demand.